RECOMMENDED PRODUCTS

COMPANY PROFILE

Contact Supplier

Henan Lanning Technology Co., Ltd. is located in the historical and cultural city Shangqiu .It has superior geographical position which is in the cross (link the entrance of LianHuo highway)of Yu, Lu, Wan and Su of the four provinces. Our company belongs to government attracting investement program. We specialize in producing waste rubber refining machine, waste plastic refining machine and waste tyre refining machine.The technology has obtained environmental protection certificate and some national patents which produce oil by refining waste rubber, waste plastic and waste tyre. Whave advanced production facility, such as automatic submerged arc welding machine,ultrasonic flaw-detecting machine,CO gas shielded welding machine and so on.

Our company has strong technology power and good management ability.The products quality is also improving continually.So our products are very popular both at home and abroad.The government gives us the honor certificate:" Strictly Observe Contracts, Keep Promises",' Advanced Manufacturing Management Enterprise".The extraordinary production technology has attracted a large number of domestic and foreign customers. We have created good social and economic benefits. Our enterprise culture is "leading in the same industries, pay more attention to integrity ,innovate and realize win-win results; we develop and expand the enterprise spirits "homony,science and make progres";we also perfect our enterprise system,standardize enterprise behavior,build"Lanning"brand and improve our competitiveness,try our best to provide customers perfect service.

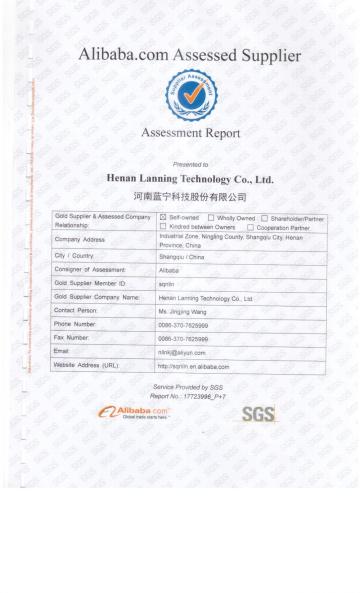

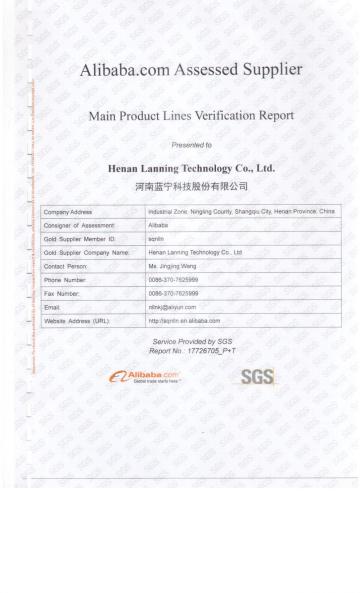

CERTIFICATES

Email to this supplier